How to Install a Water Softener: A Step-by-Step Guide for Homeowners

Imagine enjoying soap that lathers better, skin that feels smoother, and dishes that sparkle like never before. All these sound like signs of luxurious living, but they’re simply the benefits of installing a water softener in your home.

As daunting as DIY plumbing may seem, this comprehensive guide will walk green thumbs through an easy-to-follow, step-by-step process to install a water softener, and you can marvel at the substantial difference it makes in maintaining your home appliances and your overall health! So suit up; empowerment awaits in your very own utility room!

Gathering Necessary Equipment for Installation

Before you begin the installation process for a water softener, it is crucial to gather all the necessary equipment and materials. Proper preparation will ensure a smoother and more efficient installation experience. Here are some important items you will need:

- Water Softener Unit: Purchase an appropriate water softener unit based on your home’s water usage and hardness level. Consider factors such as capacity, regeneration cycle frequency, and efficiency.

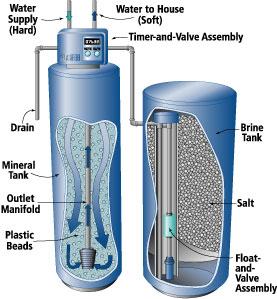

- Brine Tank: The brine tank is where the salt or potassium chloride required for the water softening process is stored. Ensure the tank size aligns with the needs of your household.

- Resin Tank: The resin tank is a critical component that houses the resin beads responsible for exchanging calcium and magnesium ions in hard water with sodium ions. Select a resin tank that suits your water consumption and fits in your designated installation area.

- Bypass Valve: A bypass valve allows you to isolate or redirect the flow of water through the water softener unit during service or maintenance.

- Mounting Hardware: Depending on your installation location, you may require mounting brackets or other hardware to secure the water softener unit.

- Drain Line Tubing: The drain line tubing is responsible for carrying wastewater from the regeneration process to an appropriate drain or utility sink.

- Plumbing Connectors and Fittings: Gather various connectors and fittings, such as pipes, elbows, tees, compression fittings, and adaptors, to connect the water softener unit to your existing plumbing system.

- Salt or Potassium Chloride: If using a traditional ion exchange system, purchase high-quality salt pellets or potassium chloride specifically designed for water softeners.

- Tools: As we move on to discussing essential tools, ensure you have them readily available before starting the installation process.

By gathering all these necessary items upfront, you can streamline your installation process without unnecessary interruptions or delays.

Essential Tools and Fittings for Water Softener Installation

To install a water softener successfully, you will need several essential tools and fittings. Here’s a list of some key items:

- Pipe Wrench: A pipe wrench is necessary for tightening and loosening pipe connections during the installation process.

- Adjustable Wrench: An adjustable wrench will be useful for securing compression fittings and other plumbing connections.

- Tubing Cutter: Use a tubing cutter to neatly cut the drain line tubing to the required length.

- Utility Knife: A utility knife will come in handy for cutting and trimming various materials, such as tubing and insulation.

- Screwdriver Set: Have a set of screwdrivers available, as screws may need to be tightened or removed during installation.

- Level: Ensure your water softener unit is properly leveled using a bubble or digital level.

- Teflon Tape: Teflon tape helps create a tight seal on threaded plumbing connections, preventing leaks.

- Pipe Sealant: Use pipe sealant on specific joints or threads where extra security against leaks is desired.

- Hole Saw Kit: If you need to drill holes for various plumbing connections, a hole saw kit with different sizes can be useful.

- Safety Glasses and Gloves: Protect your eyes from debris or splashing water by wearing safety glasses, and use gloves to keep your hands safe throughout the installation process.

Remember to always consult the manufacturer’s instructions specific to your water softener unit for any additional tools or fittings that may be required.

Setting Up the Water Softener Tank and Connections

Setting up the water softener tank and making the necessary connections is a crucial step in installing a water softener system in your home. This process ensures that the system functions effectively to remove minerals from your water supply and provide you with soft, clean water throughout your household.

First, choose a suitable location for the water softener tank. It should be placed near the main water supply line and have enough space for easy access during routine maintenance or refilling salt. Ensure that the area is dry and level to prevent any issues with stability or leakage.

Next, shut off the main water supply valve to your home. This step is essential to avoid any leaks or disruptions during the installation process. Once the water is turned off, you can proceed with installing the bypass valve assembly on the main water supply pipe. The bypass valve allows you to redirect the flow of water when needed, such as during maintenance or repairs.

Now, it’s time to connect the water softener tank to the plumbing system. Begin by attaching a short length of pipe to both ends of the bypass valve assembly. Then, connect one end of a flexible connector hose to the cold-water pipe located on top of the tank’s control valve. The other end of this hose should be connected to the bypass valve assembly.

To complete the setup, connect another flexible connector hose from the hot-water pipe (if applicable) to the corresponding port on top of the control valve. Double-check all connections for tightness, and make sure there are no leaks.

With the water softener tank and connections properly set up, it’s time to move on to the next critical aspect of installation: assembling the valve plate and valve.

Procedure for Assembling Valve Plate and Valve

Assembling the valve plate and valve is a vital part of installing a water softener system. These components help regulate the flow of water and control the regeneration process in the system. Understanding and successfully completing this procedure will ensure that your water softener functions optimally.

To begin, carefully follow the manufacturer’s instructions provided with your specific water softener unit. Each model may have slight differences in assembly, so it is crucial to refer to the manual for accurate guidance.

Typically, you will need to attach the valve plate to the control valve by aligning the notches and securing them together. Make sure they are firmly connected before moving forward.

Next, connect the valve disc to the bottom of the control valve, ensuring it fits securely into place. This disc helps direct water flow during different stages of the regeneration process.

Once these parts are assembled, insert the assembled valve plate and disc into their designated positions inside the tank. Ensure they fit correctly and securely within the tank assembly.

Lastly, attach any necessary clips, brackets, or screws according to the instructions provided. These additional components help secure everything in place and prevent any potential shifting or damage during operation.

Connecting the Salt Storage Component

When installing a water softener, one of the crucial steps is connecting the salt storage component. This part of the process ensures that your water softener has a steady supply of salt to go through the regeneration cycle and maintain its optimal performance. Let’s dive into a detailed explanation of how to connect the salt storage component.

First, locate the brine tank, which is typically a separate container near the main water softener unit. Check that it is positioned in an area with sufficient space for easy access. The brine tank contains salt, which is dissolved in water to create a brine solution used during regeneration.

Next, assemble the components necessary for connecting the salt storage. This typically involves attaching a brine tube or hose from the brine tank to a specific inlet valve on the water softener system. Refer to the manufacturer’s instructions for your specific model to ensure proper connection.

Once you have confirmed the correct positioning and connections, proceed by inserting the open end of the brine tube into the designated port on your water softener system. Ensure it fits securely to avoid any leaks or malfunctions down the line.

Afterward, connect the other end of the tube to the appropriate valve on top of the brine tank. This valve regulates the flow of brine during regeneration cycles. Again, confirm that all connections are tight and secure before moving forward.

It’s worth noting that some newer models feature automatic controls, allowing for more convenient and efficient operation. These systems may have different connection configurations, so consulting your user manual or seeking professional guidance is advisable.

Remember, proper installation and maintenance are essential if you want your water softener to function effectively and efficiently over time. Taking time during this step to ensure a solid connection between the salt storage component and your water softener system will help minimize future issues and ensure consistent performance.

Replenishing the Tank with Salt and Water Treatment Chemicals

Once you have successfully connected the salt storage component, the next step is replenishing the tank with salt and water treatment chemicals. This crucial process ensures that your water softener maintains its effectiveness in removing hardness minerals from your water supply.

Begin by checking the salt levels in the brine tank. It’s important to keep an adequate amount of salt present at all times to ensure proper regeneration. Depending on the size of your household and water usage, this may require adding several bags of salt initially or monitoring and replenishing as needed.

For instance, if you live in an area with extremely hard water, you might need to replenish the brine tank every couple of months. On the other hand, if your water isn’t excessively hard, you might only need to refill it once every six months.

To add salt, carefully pour it into the brine tank until the desired level is reached. Be mindful not to overfill it, as this can lead to clogs or other issues within the system. Some models may also require additional water treatment chemicals like resin cleaners or iron removal agents. Consult your user manual or follow manufacturer recommendations for incorporating these additives, if necessary.

After replenishing the tank, give it some time to dissolve the salt and prepare the brine solution before any regeneration cycles occur. This typically takes a few hours or longer, depending on the system’s design.

Regularly monitor the salt levels in the brine tank to ensure the consistent performance of your water softener. Additionally, be mindful of any maintenance recommendations provided by the manufacturer. Following proper maintenance procedures will help extend the lifespan of your system and avoid unnecessary repairs.

Adding auxiliary tanks for enhanced Water Softening

In some cases, homeowners may require additional water softening beyond what a single water softener unit can provide. This is particularly true for large households with high water consumption or areas with extremely hard water. To address such situations, adding auxiliary tanks can be a valuable solution to enhance the water softening process.

Auxiliary tanks work in conjunction with the main water softener unit to further reduce the mineral content in the water and ensure optimum softness. The additional tanks are installed downstream from the main unit and utilize resin beds to remove calcium and magnesium ions, which are responsible for causing hardness in water. This setup effectively doubles or triples the water softening capacity, providing even better-quality softened water.

Before installing auxiliary tanks, it’s essential to evaluate your specific requirements and consult with a professional plumber to determine the most suitable configuration. The plumber will assess factors such as water hardness levels, household size, and water usage patterns to recommend the appropriate number and size of auxiliary tanks needed.

Let’s say you have a large household with six family members and frequently experience issues with hard water affecting appliances, faucets, and laundry. A basic single-tank water softener might not be sufficient to meet your needs. In this case, adding two auxiliary tanks could significantly improve your water-softening system’s efficiency and performance.

The installation of auxiliary tanks involves connecting them in series with the existing water softener unit. The plumbing connections are made using PVC pipes or copper tubing, ensuring proper alignment and secure fittings. It’s crucial to follow the manufacturer’s instructions and local plumbing codes during the installation process.

Once installed, the auxiliary tanks should be properly programmed and calibrated to work in sync with the main unit. This includes setting regeneration schedules, recharge capacities, and other necessary parameters for optimal performance.

Remember that maintaining auxiliary tanks is equally important as caring for the main softener unit. Regular checks and maintenance, such as cleaning and resin bed replacement, will ensure continuous and efficient operation.

Verifying the Installation and Clean Up

With the installation process completed, it’s crucial to verify that the water softener system is functioning correctly before considering the job done. This involves a series of steps to ensure proper operation and evaluate any potential issues.

Firstly, check for leaks in all plumbing connections related to the water softener unit and auxiliary tanks. Even small leaks can undermine the effectiveness of the system over time. Address any leaks promptly by tightening fittings or replacing defective components.

Next, turn on your home’s water supply and observe for any irregularities in flow or pressure. Ensure that water flows smoothly through faucets, showers, and appliances without any signs of blockage or restriction.

Lastly, go through a thorough cleaning process to tidy up any mess created during installation. Wipe down surfaces, clean up excess debris or materials, and restore everything to its original state.

Pay attention to any specific post-installation instructions provided by the manufacturer regarding regular maintenance, settings adjustments, or recommended servicing intervals. Adhering to these guidelines will help extend the lifespan of your water softener system while ensuring optimal performance.

Final Words

At JBK Plumbers, we understand the significance of installing a water softener properly to ensure you receive only high-quality water for your home. With years of expertise and commitment to excellence behind us, JBK Plumbers stands as the go-to professionals in Saratoga Springs, Utah, for water softener installation services.

DIY installation might seem cost-effective; however, nothing beats hiring professional installers like JBK Plumbers to install your softener properly with meticulous installations from skilled technicians that ensure optimal functioning. Don’t compromise on water quality; contact JBK today for seamless water softener installations that ensure long-term efficiency and peace of mind for you and your family!